Iso class 2 500 750 air changes per hour with a ceiling coverage of 80 100.

Iso 7 clean room air changes.

See the maximum allowable concentrations by cleanroom class on our cleanroom classifications page.

Usp 797 and usp 800 cleanrooms for sterile and hazardous drug processes also have unique air change requirements.

A class 5 room can have an air change rate of 400 to 600 times per hour while a class 7 room can change at 50 to 60 changes per hour.

The recommended air changes per hour for an iso class 1 clean room is 500 750 and the ceiling coverage should be 80 100.

The chart below provides an explanation of the differences between our clean room classes.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

C recommended air changes per hour ach.

Cleanliness of any clean room is maintained by the air changes per hour.

Lower air change rates result in smaller fans which reduce both initial investment and construction cost.

A 30 percent reduction in air change rate results in a power reduction of approximately 66 percent.

A properly designed clean room must have a high rate of air changes to scrub the room of particulates.

The large air supply is mainly provided to eliminate the settling of the particulate and dilute contamination produced in the room.

Iso class 3 500 750 air changes per hour with a ceiling coverage of 60 100.

60 90 for iso 7 cleanrooms organisations typically measure micron sizes 5 0µ and 0 5µ.

In room ffu cfm cleanroom air change rates and tables for usp standards.

A flow hood within the primary control area does in fact influence the overall air change rate of the.

Iso 7 is a common clean cleanroom classification.

As an example class 10 000 cleanroom filtration systems must provide filter coverage of 15 25 and a minimum of 60 air changes per hour.

The equivalent fed standard is class 10 000 or 10 000 particles per cubic foot.

By minimizing turbulence lower airflow may improve cleanliness.

Iso 7 cleanroom applications.

Information on iso 14644 1 2015 class 7 cleanroom classification.

More air changes per hour are required for the better clean room class than the lower one.

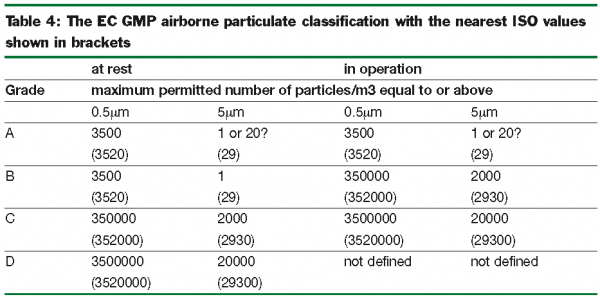

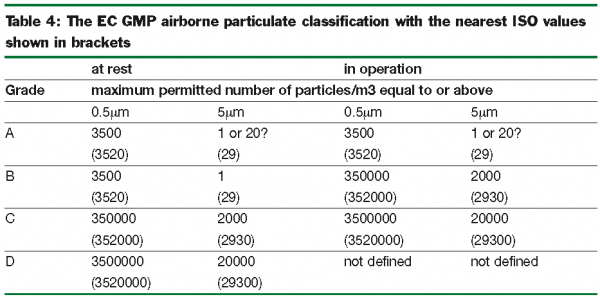

Class 10 000 associated eu gmp grade.

Fan power is proportional to the cube of air change rates or airflow.

Of ffus air changes hour 60 x cubic ft.

Whereas comfort air conditioning would require about 2 10 air changes hr a typical cleanroom would typically require 20 60 air changes and could be as high as 600 for absolute cleanliness.

A cleanroom must have less than 352 000 particles 0 5 micron per cubic meter and 60hepa filtered air changes per hour.

Federal standard 209e equivalent.