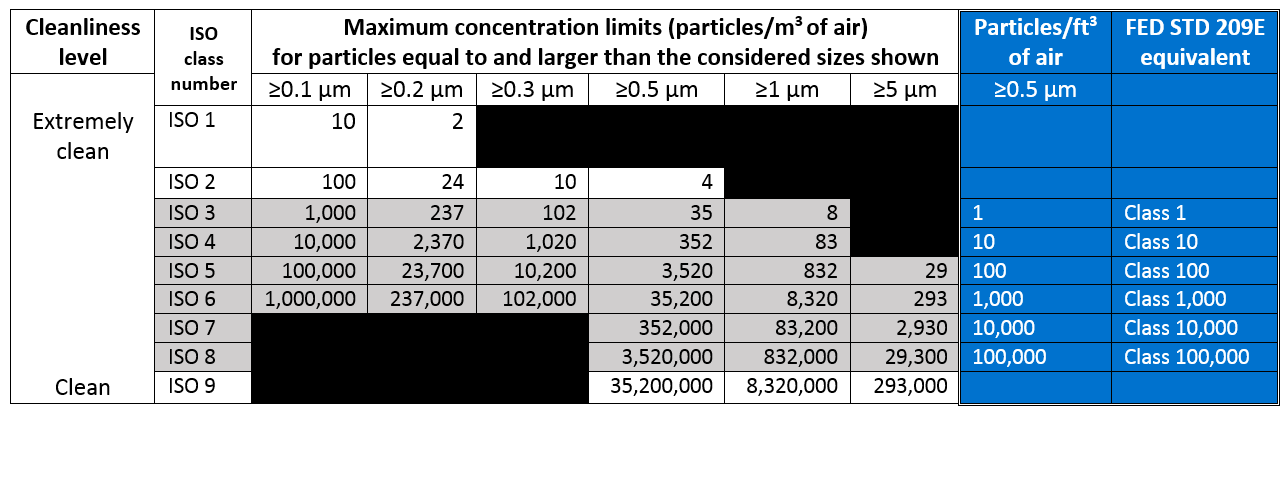

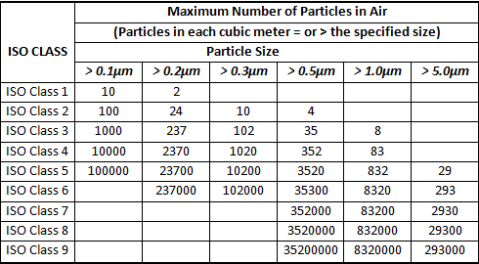

The cleanroom classification standards fs 209e and iso 14644 1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area.

Iso class 8 clean room particle count.

Iso 14644 1 and older standard fs 209e determine class by the concentration levels of particles.

In the uk british standard 5295 is used to classify cleanrooms.

No assumptions are made regarding the distribution of the actual particle counts over the area of the cleanroom or clean zone.

The basis of cleanroom standards is the micrometer or micron for short µm which is the size of the particles to be filtered.

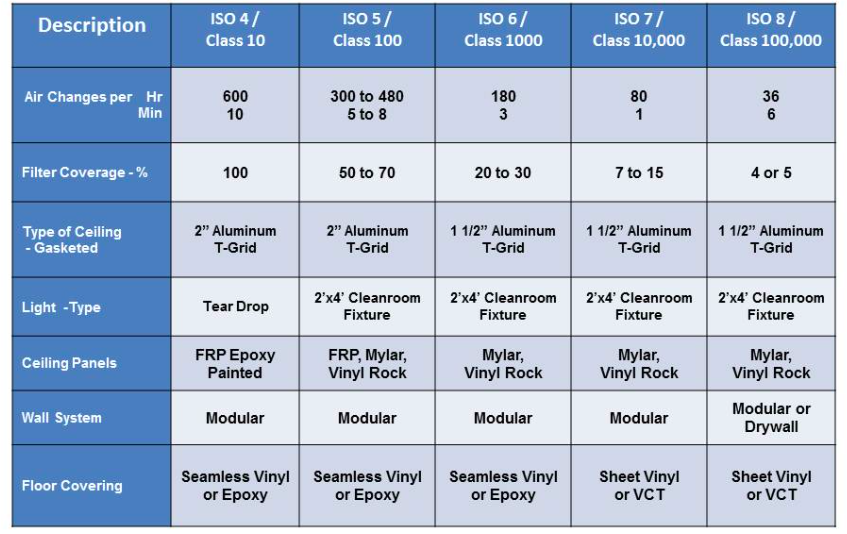

The class defines a minimum cleanliness level not a specific design.

As stated previously cleanroom classifications are based on the size and quantity of particles per volume of air.

Iso 8 cleanroom class 100 000 let.

Through its members it brings together experts to share knowledge and develop voluntary consensus based market relevant international standards that support innovation and provide solutions to global challenges.

The particles range in size from 1 5 microns µm.

However class will greatly impact design considerations such as filtration hvac requirements and other design elements.

Acceptable the ante room met an iso 14644 class 8 environment in a dynamic operating condition with an upper confidence limit of 1 784 771 0 5 particles per cubic meter.

Cleanrooms are designed to maintain extremely low levels of particulates such as dust airborne organisms or vaporized particles.

Iso class 8 cleanroom particle count.

Iso 8 cleanrooms also known as class 100 000 cleanrooms can be modular or soft walled and have a maximum particle count of 100 000 particles 0 5 um per cubic foot of interior air.

To meet requirements of a clean room as defined by federal standard 209e and newer iso standards all clean rooms must not exceed a particulate count as specified in the air cleanliness class.

Cleanroom classification particle count.

As stated before cleanrooms are classified by how clean the air is according to the quantity and size of particles per volume of air.

The micrometre µm is the basis of any cleanroom standard referring to the size of particles to be filtered from the cleanroom.

Iso is an independent non governmental international organization with a membership of 162 national standards bodies.

The molding cleanroom μ met an iso 14644 class 8 environment in a dynamic operating condition with an average of.

Particle count classification room status.

While in iso 14644 1 1999 an underlying assumption was that the particle counts follow the same normal distribution across the room this assumption has now been discarded to allow the sampling to be used in rooms where.